Force Fit

In terms of manufacturability, answer the following about a

force fit:

- Is the fit type Clearance, Transition, or Interference?

- What is the ideal use case for a force fit ?

Expand Hint

Hint 2

A force fit, also known as a shrink fit, is a type of fit in which two parts are forced together in assembly.

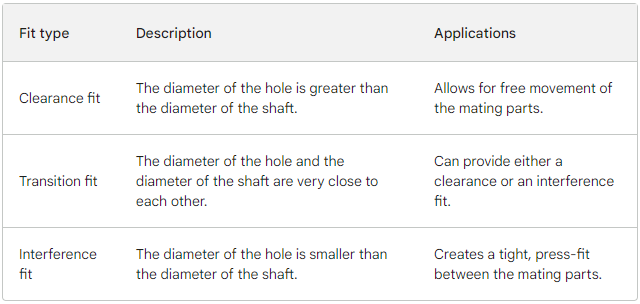

Here is a breakdown of the three different types of fits for shafts and holes that allow for an engineer to realize a specific design’s intended function:

- Clearance fit is a type of fit in which the diameter of the hole is greater than the diameter of the shaft. This type of fit allows for free movement of the mating parts, and it is often used in applications where the parts need to be able to slide or rotate easily.

- Transition fit is a type of fit in which the diameter of the hole and the diameter of the shaft are very close to each other. This type of fit can provide either a clearance or an interference fit, depending on the exact dimensions of the parts. Transition fits are often used in applications where the parts need to be held in place tightly, but where a small amount of movement is still allowed.

- Interference fit is a type of fit in which the diameter of the hole is smaller than the diameter of the shaft. This type of fit creates a tight, press-fit between the mating parts, and it is often used in applications where the parts need to be held in place very securely.

A force fit, also known as a shrink fit, is a type of fit in which two parts are forced together in assembly, creating an interference fit. This means that the shaft is slightly larger than the hole it’s being inserted into, resulting in a large force requirement to create the tight connection. It is intended for parts that can be subjected to high stress, or for shrink fits where the heavy pressing forces needed are impractical but an interference fit is still necessary. The benefits of this fit include high strength and rigidity, increased precision and accuracy, and reduced vibration etc. However, creating force fits can be difficult to manufacture due to tight tolerances and require extra time to assemble, which all increase costs.

- Interference

- It is intended for parts that can be subjected to high stress, or for shrink fits where the heavy pressing forces needed are impractical but an interference fit is still necessary.

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Some Preferred Fits

642. Free Running Fit

Similar Problems from FE Section: Manufacturability

268. Installing a Bearing

642. Free Running Fit