Chrome Silicon Wire

A chrome silicon wire with a diameter of 10 cm will be used as a spring material in a static assembly. Approximate the max allowable torsional stress for the wire.

Expand Hint

The max allowable torsional stress for hardened and tempered carbon and low-alloy steels in static applications can be approximated as:

$$$S_{sy}=\tau = 0.50\times S_{ut}$$$

Hint 2

For spring materials, the minimum tensile strength for common spring steels can be determined from:

$$$S_{ut}=\frac{A}{d^{m}}$$$

where

$$S_{ut}$$

is the tensile strength in MPa, and

$$d$$

is the wire diameter in millimeters.

The max allowable torsional stress for hardened and tempered carbon and low-alloy steels (ASTM A232 & A401) in static applications can be approximated as:

$$$S_{sy}=\tau = 0.50\times S_{ut}$$$

For spring materials, the minimum tensile strength for common spring steels can be determined from:

$$$S_{ut}=\frac{A}{d^{m}}$$$

where

$$S_{ut}$$

is the tensile strength in MPa,

$$d$$

is the wire diameter in millimeters, and

$$A$$

and

$$m$$

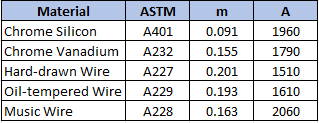

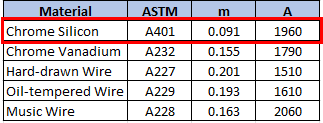

can be found in the shown table:

Since the problem is asking for a chrome silicon wire:

$$$S_{ut}=\frac{1960}{(100mm)^{0.091}}=\frac{1960}{1.521}=1,289\: MPa$$$

Thus, the max allowable torsional stress for a chrome silicon wire is approximately:

$$$\tau = 0.50\times (1,289MPa)=645\:MPa$$$

645 MPa

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Springs

135. Helical Spring

141. Tensile Strength for Springs

205. Compression Spring

206. Spring Force

265. Mechanical Springs

335. Spring Stretch

339. Compressing a Spring

341. Parallel Springs

343. Springs in Series

371. Spring Compression

381. Series of Springs

384. Springs in Parallel

386. Compounding Springs

387. Spring Tensile Strength

388. Torsional Stress

456. Free Length Spring

478. Spring Stretching

484. Correction Factor

486. Bending Stress

574. Spring Load

575. ASTM 232

576. Applied Force

Similar Problems from FE Section: Mechanical Design and Analysis

135. Helical Spring

141. Tensile Strength for Springs

205. Compression Spring

206. Spring Force

265. Mechanical Springs

280. Joint Shear Stress

295. Planetary Gear

296. Roller Bearing

299. Ball Bearing

335. Spring Stretch

337. Power Screw

339. Compressing a Spring

341. Parallel Springs

343. Springs in Series

347. Bolt Diameter

371. Spring Compression

381. Series of Springs

384. Springs in Parallel

386. Compounding Springs

387. Spring Tensile Strength

388. Torsional Stress

456. Free Length Spring

458. Rivet Strength

478. Spring Stretching

480. Threaded Fastener Load

481. Max Tension Load

483. Fatigue Loading

484. Correction Factor

485. Mean Stress

486. Bending Stress

516. Power Screw Torque

520. Power Screw Load

540. Bearing

547. Power Screw Lead

565. Design Life

574. Spring Load

575. ASTM 232

576. Applied Force

577. Preload

589. Threaded Load

590. Minimum Tensile

591. Joint Coefficient

594. Threaded Preload

596. Tensile Area

603. Bearing Type

630. Type of Bearing