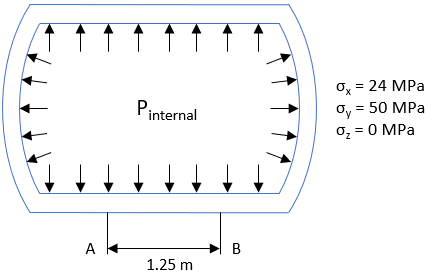

Unpressurized Vessel

The shown cross section is of an unpressurized tank vessel with a modulus of elasticity of 200x10^3 MPa, a Poisson’s ratio of 0.25, a coefficient of thermal expansion of 0.000012 m/m°C, and a yield strength of 350 MPa. If the internal pressure were to increase to P such that the wall stresses between Points A & B are below, what is the increased length (along the outer wall) between Points A & B in mm?

Expand Hint

For longitudinal strain without a temperature rise:

$$$\varepsilon_{x}=\frac{1}{E}[\sigma_x-\nu(\sigma_y+\sigma_z)]$$$

where

$$E$$

is the modulus of elasticity,

$$\nu$$

is Poisson’s ratio, and

$$\sigma$$

is the normal stress.

Hint 2

Engineering strain:

$$$\varepsilon=\frac{\Delta L}{L_o}$$$

where

$$\Delta L$$

is the change in length of member, and

$$L_o$$

is the original member length.

For longitudinal strain without a temperature rise:

$$$\varepsilon_{x}=\frac{1}{E}[\sigma_x-\nu(\sigma_y+\sigma_z)]$$$

where

$$E$$

is the modulus of elasticity,

$$\nu$$

is Poisson’s ratio, and

$$\sigma$$

is the normal stress.

$$$\varepsilon_{x}=\frac{1}{200\cdot 10^3MPa}[24MPa-(0.25)(50MPa+0MPa)]$$$

$$$=\frac{1}{200\cdot 10^3MPa}[24MPa-12.5MPa]=\frac{11.5}{200\cdot 10^3}=5.75\cdot 10^{-5}$$$

For engineering strain:

$$$\varepsilon=\frac{\Delta L}{L_o}$$$

where

$$\Delta L$$

is the change in length of member, and

$$L_o$$

is the original member length.

$$$5.75\cdot 10^{-5}=\frac{\Delta L}{1,250mm}$$$

$$$\Delta L =5.75\cdot 10^{-5}(1,250mm)=0.072\:mm$$$

0.072 mm

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Hooke's Law

573. Hooke’s Law

Similar Problems from FE Sub Section: Engineering Strain

004. Stress and Strain

231. Subway Hand Rail

309. Strain

317. Utility Pole

350. Poisson’s Ratio

374. Test Specimen

403. Train Tracks

452. Test Coupon

573. Hooke’s Law

648. Elongating

Similar Problems from FE Section: Stress and Strain

070. In-plane Shear Stress

170. Principal Stress

559. Mohr’s Circle

573. Hooke’s Law

Similar Problems from FE Section: Definitions

002. Piston Basics

004. Stress and Strain

007. Aluminum Alloy Graphs

032. Viscosity Variations

074. Dynamic Viscosity

084. Specific Gravity

174. Elongation

202. Uniaxial Loading

214. Steam Engine Piston

231. Subway Hand Rail

235. Kinematic Viscosity

309. Strain

317. Utility Pole

332. Bulk Modulus of Elasticity

349. Compressibility Modulus

350. Poisson’s Ratio

374. Test Specimen

403. Train Tracks

446. Viscous Density

451. Poisson

452. Test Coupon

453. Shear Stress & Strain

460. Shear Modulus

463. Newtonian Fluid

467. Bulk vs Shear Modulus

469. Flow Characterization

479. Piston Loading

527. S.G.

530. Spec Weight

534. SW

573. Hooke’s Law

580. Modulus of Elasticity

648. Elongating