GTOL Rule #1

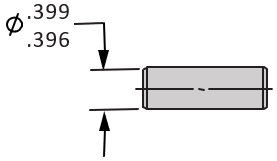

For the pin shown, answer the following questions:

- According to Rule #1, also known as the limits of size, the size tolerance applied to a feature of size controls what?

- What is the max amount of bow allowed on the pin?

- If the pin were produced at a diameter size of .399, what is the max form variation allowed?

Expand Hint

Per ASME Y14.5, Rule #1 is:

“Where only a tolerance of size is specified, the limits of size of an individual feature prescribe the extent to which variations in its geometric form as well as size, are allowed.”

Hint 2

The feature’s form may vary within the size limits. At MMC, the form must be perfect. As the it drifts from MMC to LMC, the feature may be more bent, tapered, or out of round. This guarantees fitment at the next level assembly.

The limits of size (Taylor Principle, Envelope Principle, Rule #1) defines the form and size limits of individual, regular features. For most common situations, it requires perfect form at Max Material Condition (MMC) to ensure a component will fit inside an opening. Per ASME Y14.5:

“Where only a tolerance of size is specified, the limits of size of an individual feature prescribe the extent to which variations in its geometric form as well as size, are allowed.”

The feature’s form may vary within the size limits. At MMC, the form must be perfect. As the it drifts from MMC to LMC, the feature may be more bent, tapered, or out of round. This guarantees fitment at the next level assembly.

Thus, Rule #1 controls size and form. To find the max bow allowed:

$$$.399-.396=.003$$$

Since .399 is the MMC, then the form must be perfect. So, the max form variation allowed is: .000

- Size and Form

- .003

- .000

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Modifying Symbols

053. GD&T

072. Tolerance Analysis

215. Positional Tolerance

402. GTOL

404. Feature Control Frame

409. GDT Symbols

411. GDT Rule #1

415. Geometric Symbols

417. ASME Y14.5 Symbols

421. RFS Boundaries

422. LMC Boundaries

423. MMC Boundaries

425. A Hole’s Virtual Size

426. A Pin’s Virtual Size

427. MMC Hole’s Virtual Size

428. MMC Pin’s Virtual Size

438. Accept or Reject?

Similar Problems from FE Section: Geometric Dimensioning and Tolerancing (GD&T)

053. GD&T

072. Tolerance Analysis

092. MMC vs LMC

215. Positional Tolerance

398. MMC & LMC

402. GTOL

404. Feature Control Frame

409. GDT Symbols

411. GDT Rule #1

415. Geometric Symbols

417. ASME Y14.5 Symbols

421. RFS Boundaries

422. LMC Boundaries

423. MMC Boundaries

425. A Hole’s Virtual Size

426. A Pin’s Virtual Size

427. MMC Hole’s Virtual Size

428. MMC Pin’s Virtual Size

438. Accept or Reject?