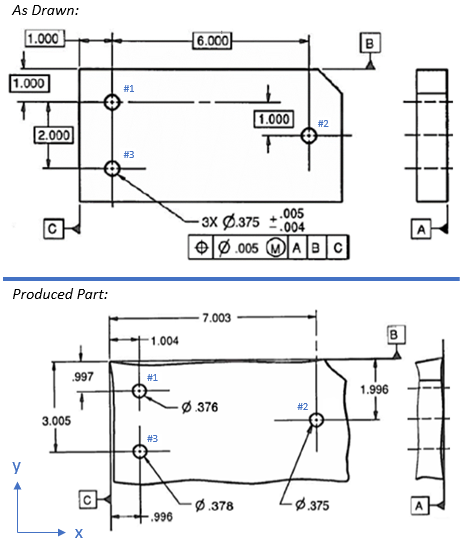

Accept or Reject?

Compare the produced part dimensions to the drawing requirements shown. Based on the positional tolerances, which hole number(s) would pass an inspection? Which hole number(s) would be rejected?

Expand Hint

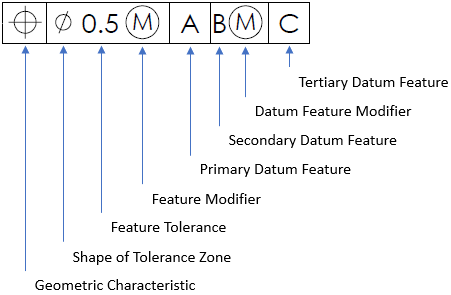

Breaking down the general parts of a feature control frame:

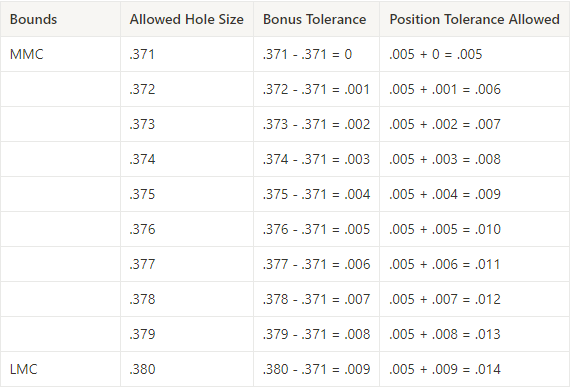

The drawing specifies a Max Material Condition (MMC) feature modifier for the .005 dia positional tolerance. A MMC modifier is the condition in which a feature of size contains the maximum amount of material within the stated limits of size. For a hole, MMC is the dimension that produces the smallest cutout. Thus,

$$$MMC_{hole}=.375-.004=.371$$$

Hint 2

Breaking down the general parts of a feature control frame:

The drawing specifies a Max Material Condition (MMC) feature modifier for the .005 dia positional tolerance. A MMC modifier is the condition in which a feature of size contains the maximum amount of material within the stated limits of size. For a hole, MMC is the dimension that produces the smallest cutout. Thus,

$$$MMC_{hole}=.375-.004=.371$$$

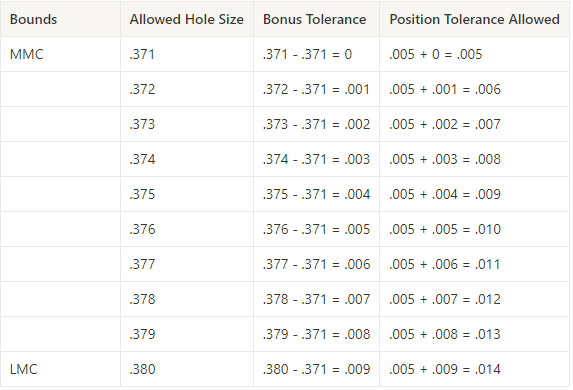

For a positional tolerance with a MMC feature modifier, there is a linearly increasing bonus tolerance as the actual hole size leans closer to LMC. LMC, or Least Material Condition, is the version of a feature that contains the least amount of material within the called out size limits. For a hole, LMC is the dimension that produces the largest cutout. Thus,

$$$LMC_{hole}=.375+.005=.380$$$

Now that the upper (LMC) and lower (MMC) bounds for hole size is determined, let’s calculate the bonus tolerances to find the total positional tolerance allowed for each hole size.

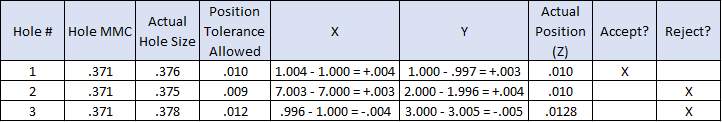

To find the actual hole position on the produced part:

$$$Z=2\sqrt{X^2+Y^2}$$$

where

$$X$$

is the difference between the x-coordinate hole position on the produced part and the drawing’s basic dimension associated with the hole’s x-direction, and

$$Y$$

is the difference between the y-coordinate hole position on the produced part and the drawing’s basic dimension associated with the hole’s y-direction. Make sure to track +/- directions based on the established coordinate system.

A manufactured hole would be accepted/pass inspection if:

$$$Z\leq Position\:Tolerance\:Allowed$$$

A manufactured hole would be rejected/fail inspection if:

$$$Z> Position\:Tolerance\:Allowed$$$

Thus,

#1: Accept

#2: Reject

#3: Reject

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Definitions used in ASME Y14.5

092. MMC vs LMC

215. Positional Tolerance

398. MMC & LMC

402. GTOL

404. Feature Control Frame

425. A Hole’s Virtual Size

426. A Pin’s Virtual Size

427. MMC Hole’s Virtual Size

428. MMC Pin’s Virtual Size

Similar Problems from FE Sub Section: Modifying Symbols

053. GD&T

072. Tolerance Analysis

215. Positional Tolerance

402. GTOL

404. Feature Control Frame

409. GDT Symbols

411. GDT Rule #1

414. GTOL Rule #1

415. Geometric Symbols

417. ASME Y14.5 Symbols

421. RFS Boundaries

422. LMC Boundaries

423. MMC Boundaries

425. A Hole’s Virtual Size

426. A Pin’s Virtual Size

427. MMC Hole’s Virtual Size

428. MMC Pin’s Virtual Size

Similar Problems from FE Section: Geometric Dimensioning and Tolerancing (GD&T)

053. GD&T

072. Tolerance Analysis

092. MMC vs LMC

215. Positional Tolerance

398. MMC & LMC

402. GTOL

404. Feature Control Frame

409. GDT Symbols

411. GDT Rule #1

414. GTOL Rule #1

415. Geometric Symbols

417. ASME Y14.5 Symbols

421. RFS Boundaries

422. LMC Boundaries

423. MMC Boundaries

425. A Hole’s Virtual Size

426. A Pin’s Virtual Size

427. MMC Hole’s Virtual Size

428. MMC Pin’s Virtual Size