Critical Crack Length

Consider a part is formed by bending a sheet of 4340 Steel, which has a Fracture Toughness of 46 MPa∙m^(1/2), and a yield strength of 470 MPa. What is the max crack length that can be tolerated for an exterior crack in mm?

Expand Hint

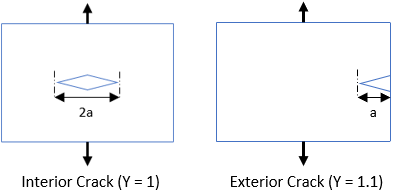

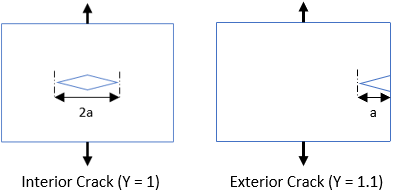

$$$K_{IC}=Y\cdot \sigma \cdot \sqrt{\pi (a)}$$$

where

$$K_{IC}$$

is fracture toughness,

$$\sigma$$

is applied stress,

$$a$$

is crack length, and

$$Y$$

is geometrical factor.

Hint 2

Fracture toughness is the stress intensity of when a brittle material will fail due to the combination of an applied stress and crack length.

$$$K_{IC}=Y\cdot \sigma \cdot \sqrt{\pi (a)}$$$

where

$$K_{IC}$$

is fracture toughness,

$$\sigma$$

is applied stress,

$$a$$

is crack length, and

$$Y$$

is geometrical factor.

Based on the problem statement:

- $$\sigma=470\:MPa$$

- $$Y=1.1$$ (since an exterior crack will be produced)

- $$K_{IC}=46\:MPa\cdot m^{1/2}$$

Solving for crack length:

$$$a=\left (\frac{K_{IC}}{Y\cdot \sigma} \right )^2\cdot \frac{1}{\pi}$$$

$$$a=\left (\frac{46MPa\cdot \sqrt{m}}{(1.1)(470MPa)} \right )^2\cdot \frac{1}{\pi}=\frac{0.0079m}{\pi }=0.0025=2.5\:mm$$$

2.5 mm

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Mechanical

004. Stress and Strain

007. Aluminum Alloy Graphs

076. Stress vs Strain Curves

167. Material Crack

172. Tensile Test

315. Composite Material

319. Composite Strain

349. Compressibility Modulus

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

407. Composite Modulus

445. Fracture Toughness

455. Fracture Stress

495. Yield and Ultimate Strength

538. Fracture

636. Base Material

653. Goodman vs Soderberg

Similar Problems from FE Section: Properties of Materials

004. Stress and Strain

007. Aluminum Alloy Graphs

076. Stress vs Strain Curves

167. Material Crack

172. Tensile Test

315. Composite Material

319. Composite Strain

349. Compressibility Modulus

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

407. Composite Modulus

445. Fracture Toughness

455. Fracture Stress

495. Yield and Ultimate Strength

538. Fracture

542. Resistivity

544. Conductivity

636. Base Material

653. Goodman vs Soderberg