Base Material

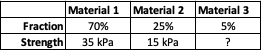

A composite material with a strain of 0.09 and a modulus of elasticity of 400 kPa is made up of three base materials from the shown table. What is base Material 3’s strength in kPa?

Expand Hint

Hooke’s Law:

$$$\sigma=E\varepsilon $$$

where

$$\sigma$$

is the stress,

$$E$$

is the elastic modulus (modulus of elasticity or Young’s modulus), and

$$\varepsilon $$

is the strain.

Hint 2

$$$\sigma_c=\sum f_i\sigma_i$$$

where

$$\sigma_c$$

is the strength parallel to the fiber direction,

$$f_i$$

is the volume fraction of the individual material, and

$$\sigma_i$$

is the individual material’s strength.

Hooke’s Law:

$$$\sigma=E\varepsilon $$$

where

$$\sigma$$

is the stress,

$$E$$

is the elastic modulus (modulus of elasticity or Young’s modulus), and

$$\varepsilon $$

is the strain.

$$$\sigma =(400kPa)(0.09)=36\:kPa$$$

A composite material is a material formed from two or more “base” materials. The base/basic materials have notably dissimilar physical or chemical properties, but when merged to create a composite, produce properties unlike the individual elements. To find a composite’s strength:

$$$\sigma_c=\sum f_i\sigma_i$$$

where

$$\sigma_c$$

is the strength parallel to the fiber direction,

$$f_i$$

is the volume fraction of the individual material, and

$$\sigma_i$$

is the individual material’s strength.

$$$\sigma_c=f_1 \sigma_1+f_2\sigma_2+f_3\sigma_3=36\:kPa$$$

Thus,

$$$36kPa=(0.7)(35kPa)+(0.25)(15kPa)+(0.05)\sigma_3$$$

$$$36kPa=24.5kPa+3.75kPa+(0.05)\sigma_3$$$

$$$\sigma_3=\frac{7.75kPa}{0.05}=155\:kPa$$$

155 kPa

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Composite Strength

315. Composite Material

319. Composite Strain

407. Composite Modulus

Similar Problems from FE Sub Section: Mechanical

004. Stress and Strain

007. Aluminum Alloy Graphs

076. Stress vs Strain Curves

167. Material Crack

172. Tensile Test

200. Critical Crack Length

315. Composite Material

319. Composite Strain

349. Compressibility Modulus

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

407. Composite Modulus

445. Fracture Toughness

455. Fracture Stress

495. Yield and Ultimate Strength

538. Fracture

653. Goodman vs Soderberg

Similar Problems from FE Section: Composite Materials

315. Composite Material

319. Composite Strain

407. Composite Modulus

Similar Problems from FE Section: Properties of Materials

004. Stress and Strain

007. Aluminum Alloy Graphs

076. Stress vs Strain Curves

167. Material Crack

172. Tensile Test

200. Critical Crack Length

315. Composite Material

319. Composite Strain

349. Compressibility Modulus

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

407. Composite Modulus

445. Fracture Toughness

455. Fracture Stress

495. Yield and Ultimate Strength

538. Fracture

542. Resistivity

544. Conductivity

653. Goodman vs Soderberg