Aluminum Alloy Graphs

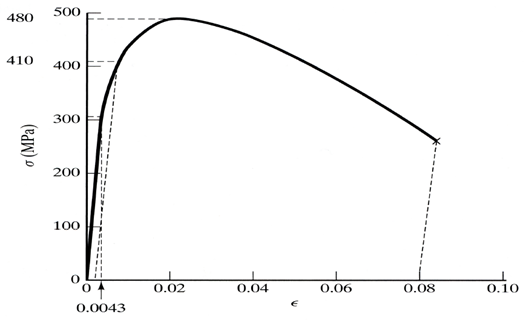

The plot below shows a stress-strain plot for tensile testing an aluminum alloy specimen. Determine the following parameters from this data:

- What is the Elastic Modulus of this material in GPa?

- What is the Tensile Strength of this alloy in MPa?

- What is the Yield Strength of this alloy in GPa?

- What is the ductility of this alloy in %?

Expand Hint

To find the Elastic Modulus, we need to calculate the slope (rise over run) of the initial loading.

Hint 2

Tensile Strength is the highest inflection point. The ductility is determined from the strain at unloading.

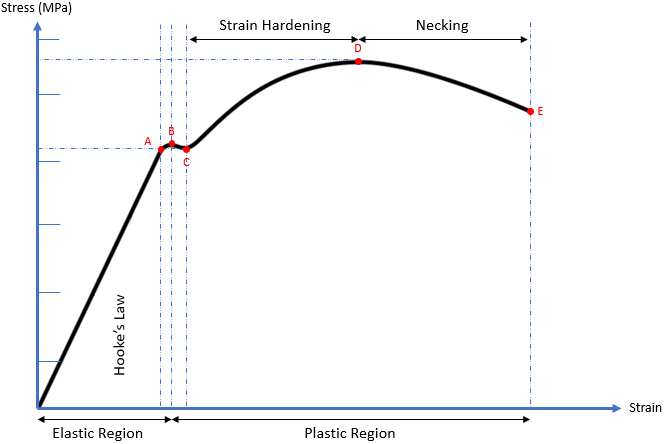

Breaking down the stress vs strain curve:

From the origin to Point A, the ductile material is subjected to stress, resulting in a proportional strain. Young’s modulus (modulus of elasticity) is the slope (rise over run) of this section and is the proportionality constant that relates stress (

$$\sigma)$$

and strain (

$$\varepsilon$$

). The straight line implies Hooke’s Law (

$$\sigma=E \varepsilon$$

) is applicable.

From Points A to B, the slope becomes non-linear (Hooke’s Law is not applicable), but deformation is still elastic (the material will return to its original shape). As a result, Point A is known as the proportional limit and Point B is called the elastic point or the upper yield point (the max force a material can withstand elastically).

Additional stress beyond the elastic point will cause the material to enter the plastic region where the material will not return to its original shape after loading (like plastic materials). From Points B to C, both elastic and plastic deformation are occurring. It is not until Point C where the material is fully deforming plastically. Point C is called the lower yield point, and is the curve’s section associated with Yield strength.

When a material undergoes plasticity, the internal molecule structure experiences constant rearrangements. The material naturally resists this change by hardening (also known as strain hardening). As increased stress is applied from Points C to D, the material will elongate along its length (growing thinner and longer) until it reaches Point D, which is the material’s max strength. This section of the curve is associated with the material’s Ultimate (tensile) strength.

Continuing past the Ultimate strength, the material experiences necking where certain cross sectional areas are reducing/elongating locally. It is no longer uniform deformation across the entire material from Points D to E. The neck will grow weaker and thinner until it physically breaks apart at Point E. Point E is known as the fracture or rupture point.

To find the Elastic Modulus, let’s calculate the slope (rise over run) of the initial loading. Strain at the point of loss of linearity (~305 GPa) is the strain value 0.0043.

$$$E=\frac{305MPa}{0.0043}=70.9\:GPa$$$

Looking at the graph, the Tensile Strength is the highest inflection point.

$$$TS=480\:MPa$$$

Looking at the graph, the Yield Strength is:

$$YS=410\:GPa$$

.

Ductility (percent elongation) is the permanent engineering strain after failure. Point E is where the material fails. Because the final strain at failure is 0.08:

$$$EL=\frac{l_f-l_0}{l_0}\times 100=\varepsilon _{final} \times 100=(0.08)(100)=8$$$

where

$$l_f$$

is the final material length and

$$l_0$$

is the inital material length.

- 70.9 GPa

- 480 MPa

- 410 GPa

- 8%

Time Analysis

See how quickly you looked at the hint, solution, and answer. This is important for making sure you will finish the FE Exam in time.- Hint: Not clicked

- Solution: Not clicked

- Answer: Not clicked

Similar Problems from FE Sub Section: Mechanical

004. Stress and Strain

076. Stress vs Strain Curves

167. Material Crack

172. Tensile Test

200. Critical Crack Length

315. Composite Material

319. Composite Strain

349. Compressibility Modulus

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

407. Composite Modulus

445. Fracture Toughness

455. Fracture Stress

495. Yield and Ultimate Strength

538. Fracture

636. Base Material

653. Goodman vs Soderberg

Similar Problems from FE Sub Section: Percent Elongation

648. Elongating

Similar Problems from FE Sub Section: Stress-Strain Curve for Mild Steel

076. Stress vs Strain Curves

172. Tensile Test

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

653. Goodman vs Soderberg

Similar Problems from FE Section: Properties of Materials

004. Stress and Strain

076. Stress vs Strain Curves

167. Material Crack

172. Tensile Test

200. Critical Crack Length

315. Composite Material

319. Composite Strain

349. Compressibility Modulus

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

407. Composite Modulus

445. Fracture Toughness

455. Fracture Stress

495. Yield and Ultimate Strength

538. Fracture

542. Resistivity

544. Conductivity

636. Base Material

653. Goodman vs Soderberg

Similar Problems from FE Section: Definitions

002. Piston Basics

004. Stress and Strain

032. Viscosity Variations

074. Dynamic Viscosity

084. Specific Gravity

174. Elongation

202. Uniaxial Loading

214. Steam Engine Piston

231. Subway Hand Rail

235. Kinematic Viscosity

275. Unpressurized Vessel

309. Strain

317. Utility Pole

332. Bulk Modulus of Elasticity

349. Compressibility Modulus

350. Poisson’s Ratio

374. Test Specimen

403. Train Tracks

446. Viscous Density

451. Poisson

452. Test Coupon

453. Shear Stress & Strain

460. Shear Modulus

463. Newtonian Fluid

467. Bulk vs Shear Modulus

469. Flow Characterization

479. Piston Loading

527. S.G.

530. Spec Weight

534. SW

573. Hooke’s Law

580. Modulus of Elasticity

648. Elongating

Similar Problems from FE Section: Uniaxial Stress-Strain

076. Stress vs Strain Curves

172. Tensile Test

354. Yield vs Ultimate Strength

358. Brittle vs Ductile vs Plastic

653. Goodman vs Soderberg